- Home

- Products

- Automatic Plastic Film Product Manufacturing Line

- Computer Controlled L Shape File Folder Production Line

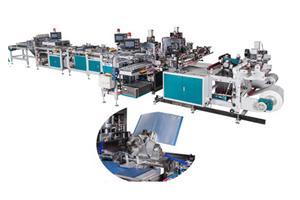

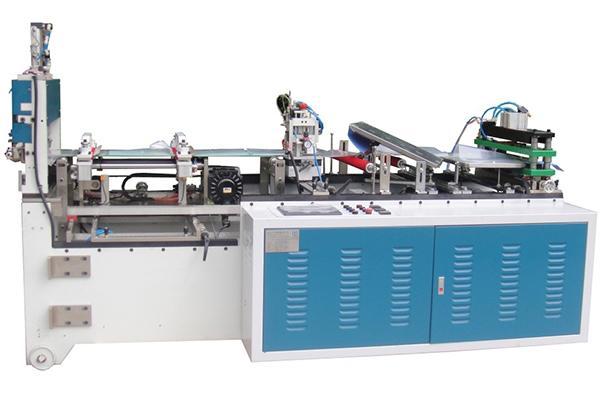

Computer Controlled L Shape File Folder Production Line

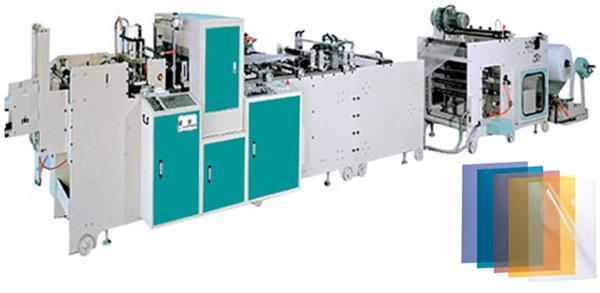

The computer controlled file folder production line completes PP and PET material integrated processing from sheet material feeding, trimming, folding, welding and cutting in order to turn them into L shaped file folders (also called E310 file folders).

A printing device can also be attached to this equipment, so that customers can print document files according to their needs.

Process display Raw materials

Raw materials Pulling

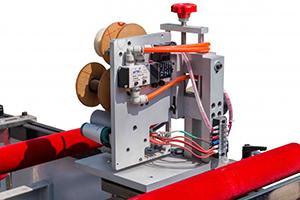

Pulling Hot stamping

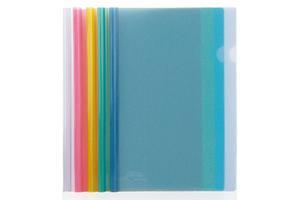

Hot stamping Finished products

Finished products

- The L shaped file folder production machine uses a fully automatic servo motor and computer control, so that the products all have the same specification and the seal is firm and beautiful.

- The entire production process, including roll materials, automatic edge aligning, trimming, folding, punching, hot stamping, ultrasonic sealing, cutting and final product collection, are all completed in a fully automatic manner with no need for manual assistance. This effectively improves production capacity and saves production costs.

- This machine carries out various precise and durable punching dies with a low fault rate. It is also equipped with electronic control to ensure the punching position is precise and does not easily deviate.

| Model | SYS-41A-400 |

| Max-Cutting Size W×L | 2500×500mm |

| Film Thickness | 0.12m-0.25mm |

| Production Per Min (PC) | 60-80 pcs/min |

| Motor | 3HP |

| Heater | 0.5KW |

| Power Required | 6.5KW |

| Machine Dimension L×W×H | 8500×1500×1400mm |

| Net Weight | 2500KG |

| Gross Weight | 2800KG |

Inquiry Form

Shantou Donghe Machinery Co., Ltd.

Tel.: +86-754-88108252

Fax: +86-754-88212222

USA - Choose Country

USA - Choose Country